Free Download ALL IN ONE UPHOLSTERY COURSE by The Lucky Needle

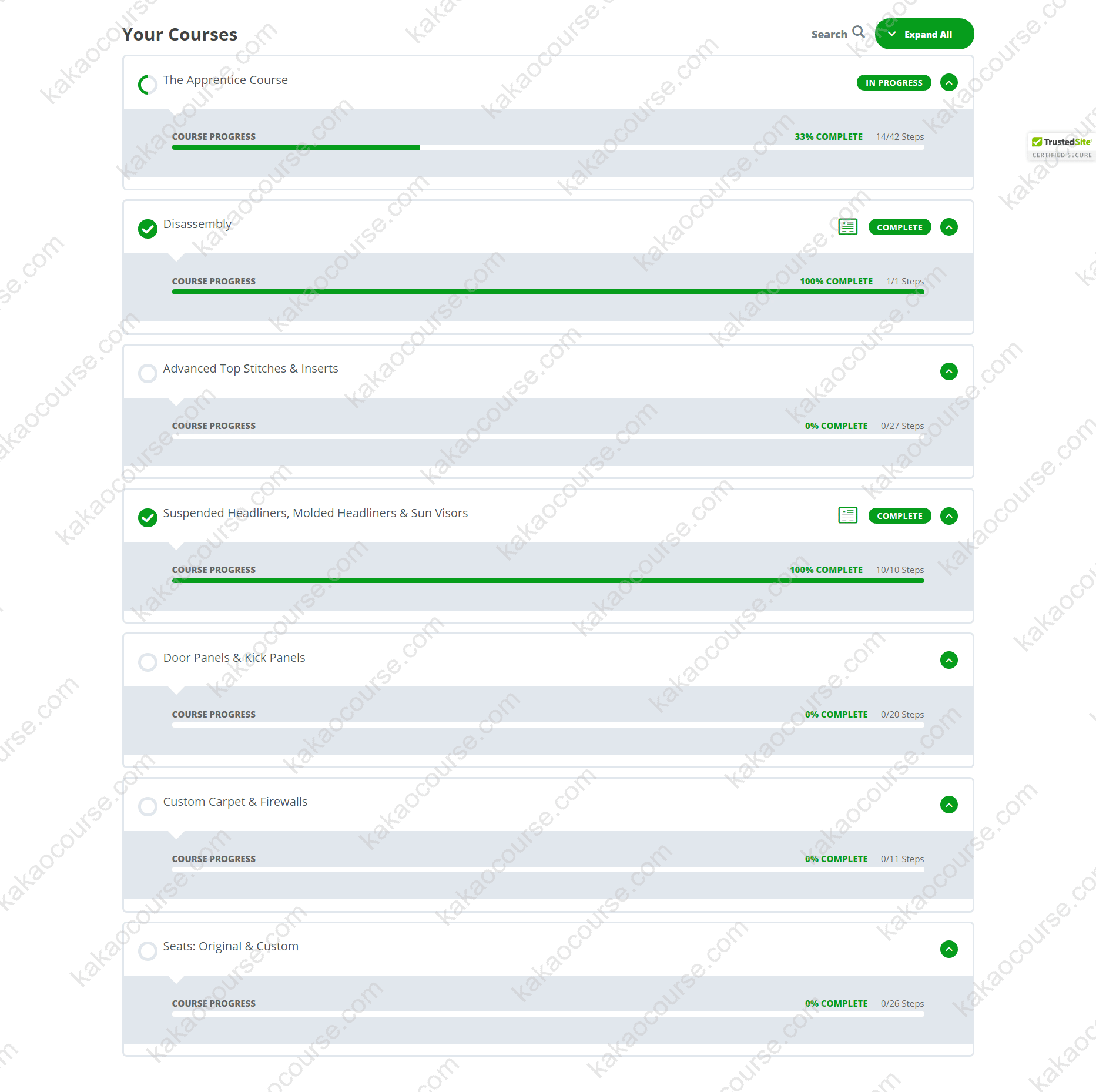

ALL IN ONE UPHOLSTERY COURSE by The Lucky Needle, Sneak Peek Inside The Course:

ALL IN ONE UPHOLSTERY COURSE by The Lucky Needle, Check Out This Free Video for Additional Information:

ALL IN ONE UPHOLSTERY COURSE by The Lucky Needle, Check Your Free PDF Sample Here:

Overview This Course

ALL IN ONE UPHOLSTERY COURSE by The Lucky Needle is a step-by-step, skills-first training program designed to take you from absolute beginner to confident automotive upholstery practitioner. Across 26.25 hours of guided instruction and 135 curated videos, you’ll learn the complete workflow—from safe teardown and pattern making to precision sewing, foam shaping, advanced top-stitching, custom carpet, headliners, sun visors, door and kick panels, and final installation. The course distills shop-floor know-how into a practical sequence you can follow at your own pace.

Unlike scattered tutorials, this program is organized around real projects and repeatable methods. Each module builds on the last, so your accuracy improves alongside your speed. You’ll develop technical fluency with industrial sewing machines and materials (vinyl, leather, foam, jute, ABS, panel board), while also learning how to plan layouts, calculate pleats, and execute pro-level finishing techniques that separate clean work from average results.

Whether you are restoring factory seats, designing custom interiors, or preparing to take on client work, the curriculum gives you a professional foundation with workflows that mirror real shop environments.

Why Should You Choose This Course?

It’s comprehensive, structured, and shop-tested. Learners often struggle because they attempt complex work before mastering fundamentals. This curriculum reverses that: you first gain control of the machine, then layer on seams, pleats, foam surgery, pattern transfer, and advanced stitching—so when you step into larger builds, you already own the muscle memory.

Key advantages at a glance:

-

Full interior coverage: Seats (original & custom), headliners (suspended and molded), sun visors, door and kick panels, custom carpet and firewalls—even troubleshooting and finishing.

-

Technique depth: From lock-stitch fundamentals and tension control to French seams, welted seams, double-stitch diamonds, tuck-and-roll, and precision panel wrapping.

-

Pattern-driven approach: Make, transfer, and refine patterns so your pieces fit tightly on the first install—less waste, better results.

-

Tools and materials clarity: Needles, feet, thread types, bobbins, staplers, contact cement, closed-cell foam, jute padding—explained with clear use-cases.

-

Practical pacing: Short, focused lessons that are easy to reference on the bench; learn in the sequence you’ll use on real jobs.

-

Professional standards: Learn to plan seams, manage nap direction, pre-fit panels, align designs, and finish edges so your interiors look intentional and consistent.

You’re not just following along; you’re building a method you can repeat on any vehicle, classic or modern, stock or custom.

What You’ll Learn

The course is organized into focused tracks that mirror an end-to-end upholstery workflow. Expect to move from fundamental machine control to complex decorative work, then to vehicle-specific projects.

1) The Apprentice Course — Absolute Foundation

Build comfort with your machine and master the building blocks that underpin all quality upholstery work.

-

Machine mastery:

-

Installing and selecting needles and feet

-

Thread types and threading order

-

Bobbin winding, installation, and tension balance

-

Stitch length selection, lock-stitch starts and stops

-

Foot pressure and foot height optimization

-

-

Seam portfolio:

-

Basic and single reinforced seams

-

French seams and welted seams (straight and curved)

-

Inside/outside corners, square corners, curved templates

-

-

Surface craft:

-

Hemming straight and curved edges

-

Carpet binding and hidden-stitch carpet binding

-

Marking methods, layout accuracy, and seam allowance discipline

-

-

Pleat calculations and execution:

-

How to calculate spacing, mark, sew, and maintain symmetry

-

-

Shop skills:

-

Staple gun handling, contact cement control, glue gun cleaning

-

Snap and grommet installation

-

Troubleshooting common sewing issues and cleaning routines

-

Outcome: Confident control of the machine and a reliable seam vocabulary you’ll use on every project.

2) Disassembly — The Start of Every Great Interior

Disassembly is where you learn to see the build before it happens.

-

Safe teardown: Documenting factory order, capturing reference photos, labeling components

-

Seat tear-down: Conserving patterns, evaluating foam and spring health, planning repairs

Outcome: You don’t guess. You deconstruct with intent so your rebuild follows a logical, efficient plan.

3) Advanced Top Stitches & Inserts — Signature Detailing

This module elevates your interiors from “repaired” to “refined.”

-

Pleats at a high level: Double-stitch pleats and hidden-stitch pleats (calculations, layout, sewing)

-

Tuck & roll families: Easy, channel, cotton-filled; how to plan, stuff, and maintain consistent channels

-

Design geometry: Diamonds, double-stitch diamonds, hourglass diamonds (template making, layout, execution)

-

Contrast elements: Pinstripes, V-points, zipper integration, double single reinforced seams

-

Channel tins: Fabricating and using tins for precise channel management

Outcome: A versatile detailing toolkit to build unique interiors with straight lines, crisp angles, and consistent spacing.

4) Suspended & Molded Headliners + Sun Visors — Clean Overhead Finishes

Learn to replace and recover headliners and visors without wrinkles or sag.

-

Patterning from the original, cutting, sewing, and installation sequence

-

Tack strip repair and replacement, windlace handling

-

Molded headliner recovering and visor rebuilding, including units with factory mirrors

Outcome: Professional overhead finishes that remain tight, aligned, and quiet over time.

5) Door Panels & Kick Panels — Structural Trim With Design Freedom

Panels are where fit, structure, and style meet.

-

Panel board selection: Types, thickness, and cutting workflows

-

Fitment and clips: Measuring, drilling, and clipping for secure, rattle-free fit

-

Closed-cell foam: Preparing, installing, and sculpting designs into foam

-

Design inserts and trim: Patterning, cutting, wrapping, and installing metal trim elements

-

Materials: Working wood panel board and ABS (sizing and sourcing guidance)

-

Finishing touches: Windlace strategies and recoloring plastic trim for a cohesive cabin

Outcome: Slim, solid panels with clean edges, accurate clip engagement, and design details that align across the cabin.

6) Custom Carpet & Firewalls — Flooring That Fits and Lies Flat

Flooring is all about smoothing, stretching, and sequencing.

-

Jute padding: Surface prep, smoothing techniques, and jute layout

-

Nap direction and wrinkle control: Planning cuts so carpet lies flat and wears evenly

-

Firewall systems: Closed-cell foam application and vinyl overlay

-

Custom floor mats: Patterning and edge finishing for a factory-plus look

Outcome: Quiet, durable floors that enhance comfort and reduce cabin noise.

7) Seats: Original & Custom — The Hero Piece of Every Build

Seats dominate the visual field and demand precision. This track shows you every step.

-

From pattern to install:

-

Making patterns from original covers, transferring and truing, cutting pieces

-

Scrim foam backing, long pleat runs, welt wrapping, and design alignment

-

Sewing backrests and cushions with consistent seam allowances

-

-

Foam work and structure:

-

Cutting and shaping foam, repairing damaged foam, fixing sagging springs

-

Building new foam forms for custom designs

-

-

Final assembly:

-

Installing covers tight and straight, recovering headrests, recoloring plastics, and aligning seams across multiple components

-

Diagnosing puckered seams and correcting awkward shapes

-

Outcome: Seat covers that install smoothly, hug the foam, and keep lines straight—on stock restorations and original customs alike.

Who Should Take This Course?

This program is intentionally inclusive. If you can commit to measured steps and careful workmanship, you can produce professional results.

-

Beginners who have never used a sewing machine: Learn machine setup, stitch control, and seam construction without overwhelm.

-

DIY restorers and customizers: Upgrade your own vehicle or a project car with shop-grade processes.

-

Apprentices and career-switchers: Build a portfolio piece by piece, demonstrate repeatable methods, and develop the competence clients look for.

-

Small shop owners and mobile trimmers: Standardize your workflow and train assistants with a single, comprehensive curriculum.

-

Designers and fabricators: Add interior upholstery to your service stack—especially patterning, foam shaping, and decorative stitching.

What you need to succeed:

-

Patience and willingness to measure more than once

-

Basic hand tools and access to a sewing machine

-

The discipline to follow a process, not just an outcome

Conclusion

Automotive upholstery rewards precision, planning, and clean execution. ALL IN ONE UPHOLSTERY COURSE by The Lucky Needle gives you a complete pathway to acquire those habits—one technique, one template, one seam at a time. You’ll learn how to break complex interiors into manageable steps, use patterns to guarantee fit, and apply finishing methods that hold up to scrutiny. By the time you finish, you won’t just “know how it’s done”—you’ll have the confidence and repeatable workflow to do it again on the next car, faster and cleaner.

With 26.25 hours of instruction across 135 lessons, the course combines foundational machine literacy with advanced decorative work and full-interior execution. The result is a practical, end-to-end skill set you can take directly to the bench—whether your goal is a personal restoration, a custom showpiece, or the beginning of a professional trimming career.

Start learning today and build interiors you’re proud to sit in, showcase, and sign your name to.

Reviews

There are no reviews yet.